Prototypes

|

|

Features

|

Problems

|

|

Prototype 1

|

·

8 big key chain laser pointer laser diodes

·

Single row

·

Hold by single acrylic plate (laser cut)

·

Skyliner™ electronics

·

8-faced mirror, continuously rotating

|

·

System not closed loop: synchronizing motor speed

with laser pulses not possible

·

Mirror way too bulky for mobile use

·

Alignment of laser diodes virtually impossible, since

the laser diode capsules are imprecise

|

|

Prototype 2

|

·

8 big laser diodes

·

Two parallel rows, interlaced

·

Hold by two parallel acrylic plates (laser cut)

·

8 secondary mirrors for laser beam alignment, mounted

on U wires

·

Left-right sweeping mirror, driven by commercial RC

servo, controlled by PWM signal created by PIC

·

Custom electronics (including small PIC controller

16F84)

·

Very high brightness and visibility of projection,

even on black backgrounds

|

·

Relies on persistence of vision principle, so only

very low refresh rate (3Hz)

·

Relatively noisy

·

Still too big for mobile use

|

|

|

Features

|

Problems

|

|

Prototype 3

|

·

8 big laser diodes

·

Two parallel rows, interlaced

·

Hold by two parallel acrylic plates

·

8 secondary mirrors for laser beam alignment

·

Custom electronics (16F84 PIC)

·

Add-on mirror assembly (3D printed)

·

Continuously rotating, two-faced mirror (single

stainless steel strip, no continuous axle), held with 3D printed parts on

each end

·

Driven by 6mm motor

·

Closed-loop system with IR LED and photodiode

|

·

Mirror not turning lightly enough: the stainless

steel strip by itself was not rigid enough, because there was no continuous

axle

·

Laser diodes not bright enough for the low duty cycle

of 360-degrees continuously rotating mirror: with a projection angle of 60

degrees, only about 8% of the time the lasers are actually on

|

|

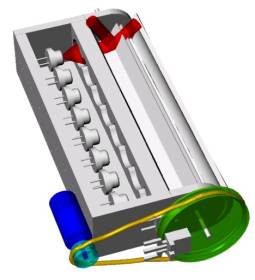

Prototype 4 (CAD model only)

|

·

8 smaller laser diodes (Lumex or Honeywell)

·

Mirror made of two strips of stainless steel and centered

axle (all the way through)

·

Continuously rotating mirror

·

Belt driven via pulleys and by 6mm motor

·

Compact size (no secondary mirrors, motor is parallel

to laser array)

·

Diodes mounted via their contact wires, for easy

alignment

|

·

Gear box difficult to align: if belt tension too

high, then friction too high; if tension too low, the belt jumps out of the

pulleys easily

·

My laser diodes not bright enough for such low duty

cycle of rotating mirror

|

|

|

Features

|

Problems

|

Prototype 5 (just holder)

|

·

8 Lumex laser diodes

·

Single row, very compact, very rugged

·

Diodes and lenses mounted directly on 3D printed

holder

|

·

Holder not precise enough, due to limitations of 3D

printing head

·

Alignment calibration not possible, and very much

necessary!

|

|

Prototype 6 (just mirror)

|

·

Continuously rotating, very light going mirror

assembly; virtually NO vibration!

·

Mirror made of single axle (centered) and 2 strips of

stainless steel, very rigid

·

Direct driven by 6mm pager motor

|

·

My laser diodes not bright enough for such low duty

cycle of rotating mirror

|

|

|

Features

|

Problems

|

|

|

Prototype 7 (just mirror)

|

·

Left-right sweeping mirror

·

Mounted on simple scotch tape hinge

·

Driven via one-arm crank (ABS) on a 6mm motor

·

Closed-loop system with IR LED and photodiode

|

·

Modest vibrations

·

With ABS crank arm very jittery projection trajectory

of the laser beams

|

|

Prototype 8 (just mirror)

|

·

Left-right sweeping mirror

·

Mounted on simple scotch tape hinge

·

Driven via one-arm crank (ABS) on a 11mm diameter

motor

·

Very high refresh rate possible!

|

·

Noisy

·

Strong vibrations

·

Relatively big

|

|

|

Features

|

Problems

|

|

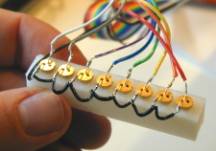

Prototype 9

|

·

8 Lumex laser diodes

·

Single, compact row

·

Separately 3D printed holder for lenses and diodes

·

Diodes mounted with U shaped double wires

·

Sweeping mirror (single strip stainless steel),

mounted on single axle at one edge of strip

·

Driven via one-arm crank (aluminum) and 6mm pager

motor

·

Closed-loop system with IR LED and photodiode

·

Refresh rate 25Hz

·

Bigger PIC (16F877) with enough memory to display all

characters

·

Serial connection

·

Can be connected to Palm Pilot™ or Java enabled

cellphone

|

·

Fragile, since all laser mountings (double wires), as

well as the motor crank, are mechanically exposed

|

|

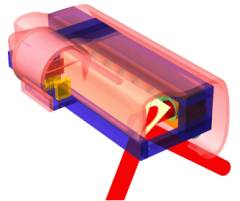

Prototype 10 (CAD model only)

|

·

Like prototype 9, but with complete housing,

protecting the laser mountings and the motor crank

|

|

Send me some comments!  Last updated February 23, 2003.

Last updated February 23, 2003.

Copyright © 1997-2004 by Stefan Marti and MIT Media Lab. All rights reserved

|